CxO Briefing: Manufacturing & Operational Efficiency

15% Reduction in Scrap and Rework Cost via AI BPMN Transformation

Production Line Quality Control

How to implement AI vision?

The Dragon1 AI BPMN Process Architect modeled the quality control workflow, implementing Vision AI for real-time inspection, immediate defect isolation, and proactive machine parameter adjustment.

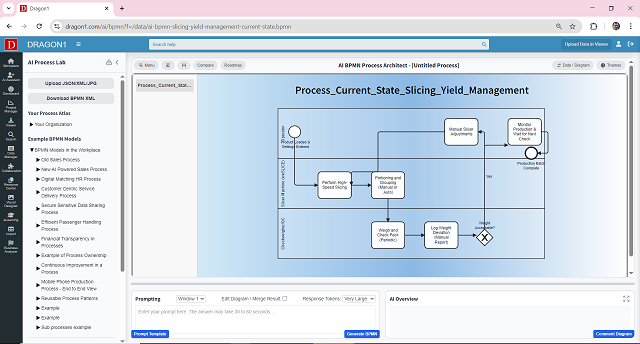

1. Current State (As-Is) - Manual or End-of-Line Sample Checking

High Scrap Rate | Delayed Rework Cost

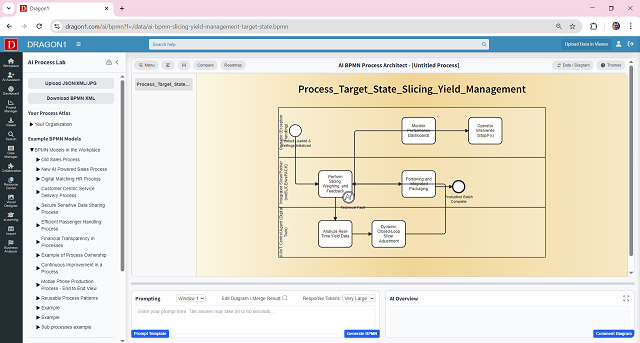

2. Future State (To-Be) - AI Vision Real-Time Inspection

Low Scrap Rate | Zero Defect Tolerance

Immediate Payback Justification

85% Modeling Efficiency: The Cost of Doing Nothing

85%

Reduction in time to create and document complex BPMN models.

€200K

Average annual cost saved from reduced material scrap and labor rework.

100%

Inspection rate achieved by Vision AI (checking every product, not just samples).

The Enterprise Result: Transformation Metrics

15%

Reduction in Scrap and Rework Cost.

Direct improvement to the bottom line by minimizing material waste and labor required to fix defects.

Real-time

Immediate Defect Isolation and Root Cause Feedback.

AI systems detect the defect and trigger machine adjustments (closed-loop control) to prevent recurrence.

Quality Jump

Attainment of Near-Zero Defect Manufacturing.

Consistent, automated inspection replaces subjective human checking, drastically improving output quality.

Detailed Process Comparison: Before and After AI

1. Current State (As-Is): The Lagging Quality Check

Quality control relies on human operators performing sample checks or inspecting only at the end of the line. Defects are often caught too late, resulting in significant batch waste and costly rework to trace the source of the issue.

| Defect Root Cause Analysis Delay | Time taken to manually identify which machine/parameter caused the defect after a faulty batch is discovered. | Lost production time (4-8 hours) while the line is halted or produces scrap until the problem is identified. |

2. Future State (To-Be): The AI-Vision Zero-Defect Blueprint

The optimized process integrates Vision AI into the production line. It inspects every product, flags defects instantly, and automatically communicates process adjustments to the machinery via a closed-loop system, minimizing scrap and ensuring consistent quality.

| AI Closed-Loop Adjustment | Vision AI identifies a defect, and an AI agent analyzes related sensor data to immediately and autonomously adjust machine parameters (e.g., temperature, pressure) to correct the process. | Defect production is stopped within minutes, proactively preventing the creation of scrap and eliminating human root-cause hunting. |