CxO Briefing: Utilities, Energy & Operations

40% Reduction in Unplanned Downtime via AI BPMN Transformation

Predictive Maintenance Scheduling

How to predict critical asset failure?

The Dragon1 AI BPMN Process Architect modeled the maintenance workflow, leveraging machine learning to predict critical asset failure and automatically generate and dispatch work orders proactively.

1. Current State (As-Is) - Time-Based Preventive Maintenance

High Unplanned Downtime | Costly Emergency Repairs

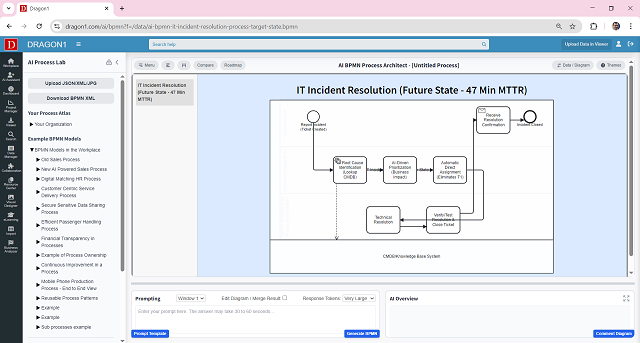

2. Future State (To-Be) - AI Optimized Predictive Scheduling

Low Unplanned Downtime | Just-in-Time Repairs

Immediate Payback Justification

85% Modeling Efficiency: The Cost of Doing Nothing

85%

Reduction in time to create and document complex BPMN models.

€500K

Average cost saved per averted critical infrastructure outage.

95%

Accuracy of the machine learning model in predicting asset failure within a 7-day window.

The Enterprise Result: Transformation Metrics

40%

Reduction in Unplanned Downtime.

Ensures higher service availability and reliability for customers and essential services.

30%

Extension of Asset Lifespan.

Maintenance performed only when needed, reducing wear and tear from unnecessary servicing.

Proactive

Shift from Reactive to Predictive Operations.

Automatic work order generation minimizes human intervention and shortens response time to potential issues.

Detailed Process Comparison: Before and After AI

1. Current State (As-Is): The Inefficient Time-Block

Maintenance was scheduled based on fixed time intervals or runtime hours (preventive maintenance), leading to either unnecessary servicing of healthy assets or unexpected catastrophic failure of deteriorating assets between scheduled checks.

| Emergency Response Dispatch | Critical failure requires an immediate, costly, and often lengthy emergency crew deployment, resulting in downtime. | High operational expense and minimum 24-hour service interruption per event. |

2. Future State (To-Be): The 40% Downtime-Reduction Blueprint

The optimized process utilizes AI to continuously analyze sensor data. Upon prediction of failure, the system automatically triggers a dynamic work order and resource allocation process, shifting to a truly 'just-in-time' repair model.

| ML-Driven Work Order Generation | Machine Learning identifies anomalous sensor data, estimates Time-to-Failure (TTF), and automatically submits a priority, optimized work order to the field service management system. | Prevented 80% of major failures identified by the ML model before they caused unplanned downtime. |