CxO Briefing: Food Production, Slicing & Quality Assurance

98% Reduction in Product Giveaway Variance via AI BPMN Yield Optimization

High-Performance Slicing and Complete Line Integration Process

The Dragon1 AI BPMN Process Architect modeled the high-speed slicing workflow, deploying AI agents (Digital Twins) to analyze real-time slice data (thickness, weight, shape) against target metrics, dynamically adjusting slicer knives and product presses to maintain perfect yield.

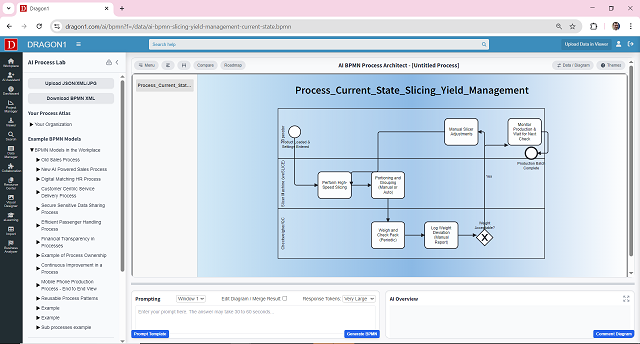

1. Current State (As-Is) - Disjointed Slicing & Manual Adjustment

3-5% Product Giveaway | High Downtime for Adjustments

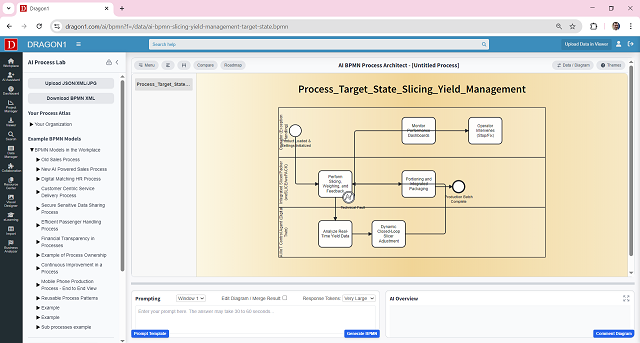

2. Future State (To-Be) - AI-Driven Integrated Yield Management

0.5% Product Giveaway | 99.9% Uptime Goal

Immediate Payback Justification

30% Production Uplift: The Cost of Doing Nothing

20%

Reduction in labor costs for quality control by automating slice weight and geometry checks.

€250K+

Average annual cost saved per line by reducing 'giveaway' (product waste over target weight) on high-value products like specialty ham or cheese.

99.9%

Accuracy in predicting and preventing machine faults (predictive maintenance) before catastrophic failure.

The Enterprise Result: Transformation Metrics

95%

Automated Dynamic Slicing Adjustment.

AI dynamically recalibrates blade speed, product pressure, and grouping patterns based on real-time data from vision systems and scales, optimizing yield.

75%

Reduction in Line Stop Events.

Predictive maintenance and real-time process control minimize unscheduled downtime, ensuring maximum throughput.

Consistency

Perfect Portion & Quality Consistency.

The integrated line ensures every pack meets the highest quality and legal weight standards, protecting the brand and reducing regulatory risk.

Detailed Process Comparison: Before and After AI Integration

1. Current State (As-Is): The Manual Guesswork Backlog

The slicing process relies on operator experience and periodic (not continuous) weight checks. Separate machines (slicer, buffer, loader, thermoformer) run independently, leading to bottlenecks and communication issues.

| Manual Weight Check & Machine Tuning | Operators stop the line every 15-30 minutes to check pack weight. Adjustments are based on trial-and-error, causing giveaway until the ideal setting is found again. | Extended changeover times (up to 2 hours) and high product giveaway variance, impacting profitability. |

2. Future State (To-Be): The AI-Driven Yield Optimization Blueprint

The Dragon1 AI BPMN Process Architect optimized the process to treat the entire line as a single integrated system (e.g., weSLICE connected to wePACK). AI agents (digital twins) continuously analyze data from sensors, scales, and vision systems, executing closed-loop adjustments for maximum efficiency.

| AI Closed-Loop Dynamic Slicing Control | AI uses real-time feedback (e.g., from a checkweigher) to instantaneously adjust the slicer's settings (e.g., blade speed, thickness profile, target weight). | Reduced the 'giveaway' margin from 3-5% to under 0.5%, and changeover time is reduced from hours to minutes, achieving near-perfect continuous operation. |